high temperature alloys price

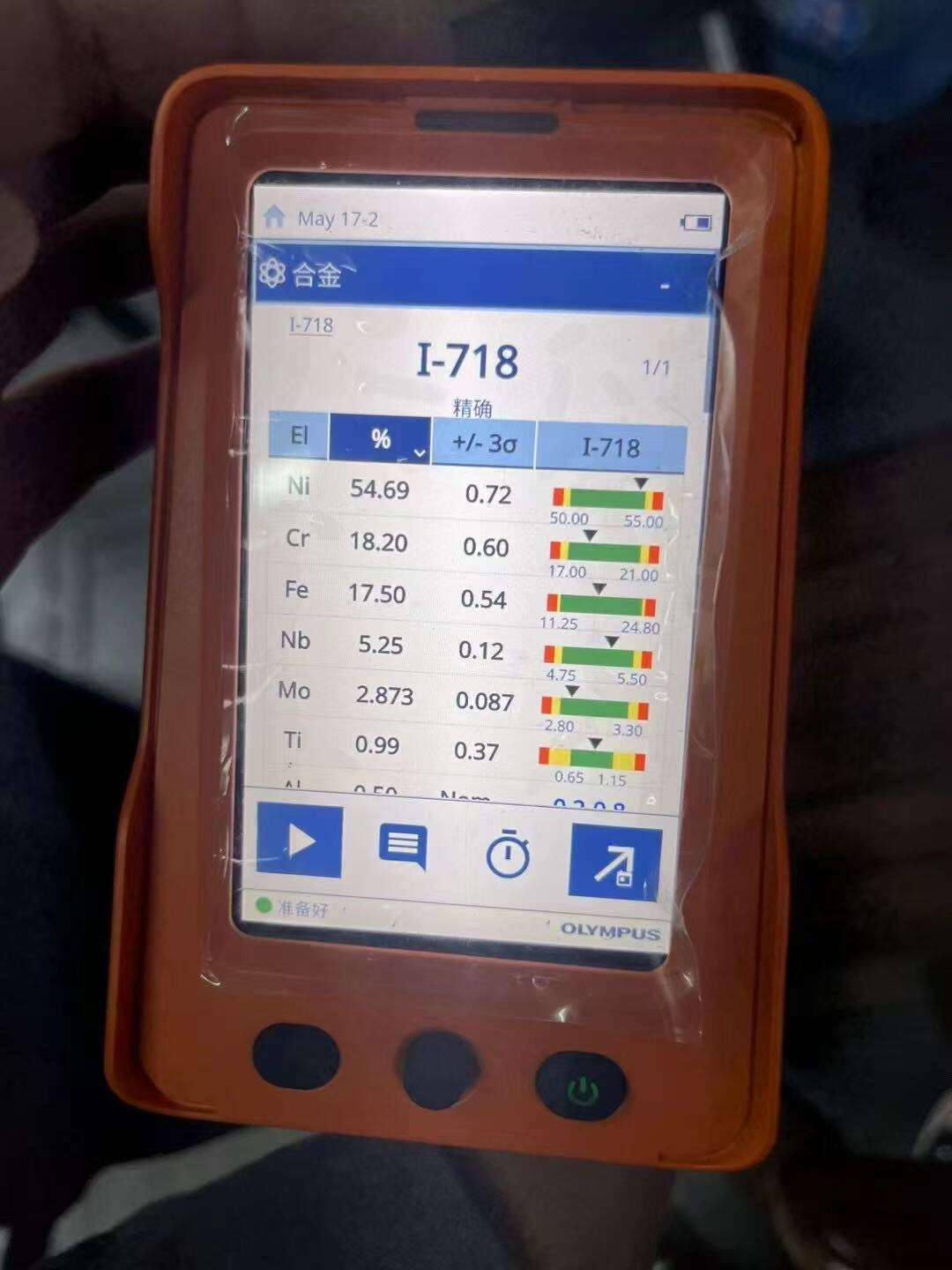

High temperature alloys price represents a critical investment consideration for industries operating under extreme thermal conditions. These specialized materials demonstrate exceptional performance capabilities when exposed to temperatures exceeding 1000 degrees Fahrenheit, making them indispensable for aerospace, power generation, and chemical processing applications. The high temperature alloys price reflects the sophisticated manufacturing processes and premium raw materials required to achieve superior heat resistance, corrosion protection, and mechanical strength retention at elevated temperatures. Understanding high temperature alloys price dynamics helps procurement professionals make informed decisions that balance performance requirements with budget constraints. These advanced materials incorporate complex compositions featuring nickel, cobalt, iron, and specialized additions like chromium, molybdenum, and tungsten. The technological features encompass outstanding creep resistance, which prevents deformation under prolonged stress at high temperatures, oxidation resistance that maintains surface integrity in harsh environments, and thermal stability that ensures consistent performance across wide temperature ranges. Manufacturing processes influence high temperature alloys price through sophisticated techniques including vacuum melting, precision casting, and specialized heat treatments. Applications span critical components such as turbine blades, combustion chambers, heat exchangers, furnace components, and petrochemical processing equipment. The high temperature alloys price justification emerges from extended service life, reduced maintenance requirements, and enhanced operational reliability. Quality certifications and material traceability contribute to high temperature alloys price premiums while ensuring compliance with stringent industry standards. Market factors affecting high temperature alloys price include raw material costs, manufacturing complexity, supply chain dynamics, and demand fluctuations across key industrial sectors. Strategic sourcing approaches help optimize high temperature alloys price negotiations while maintaining quality assurance and delivery reliability for critical applications requiring exceptional thermal performance characteristics.