high temperature alloys manufacturer

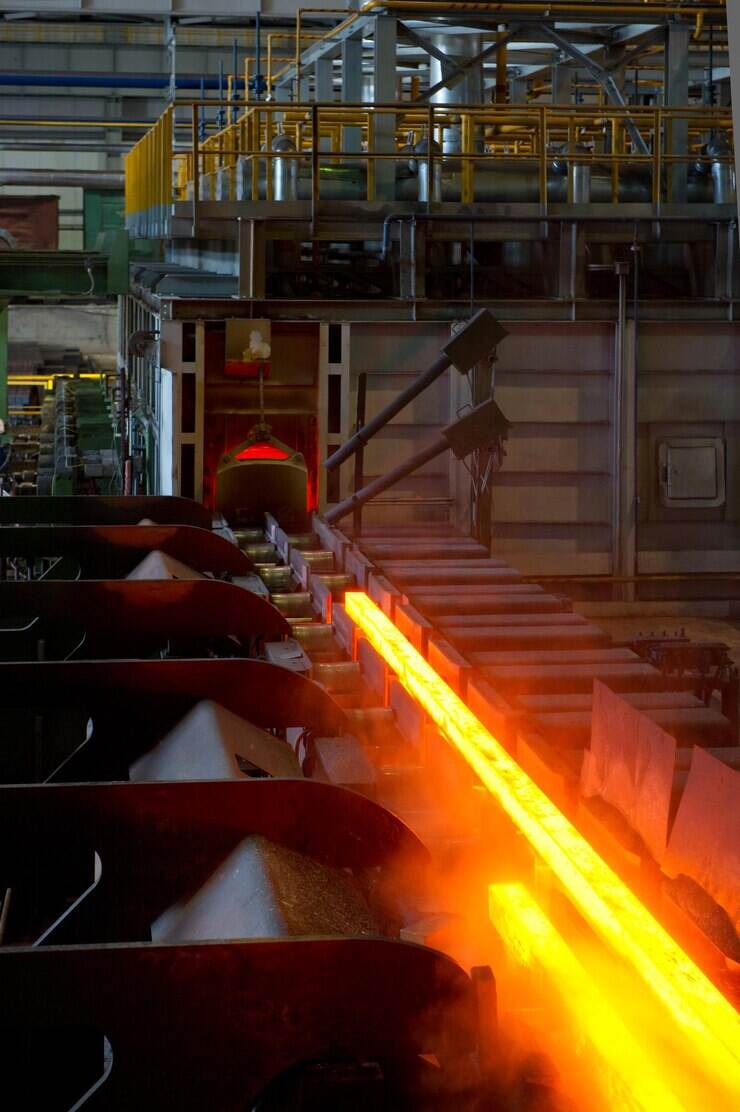

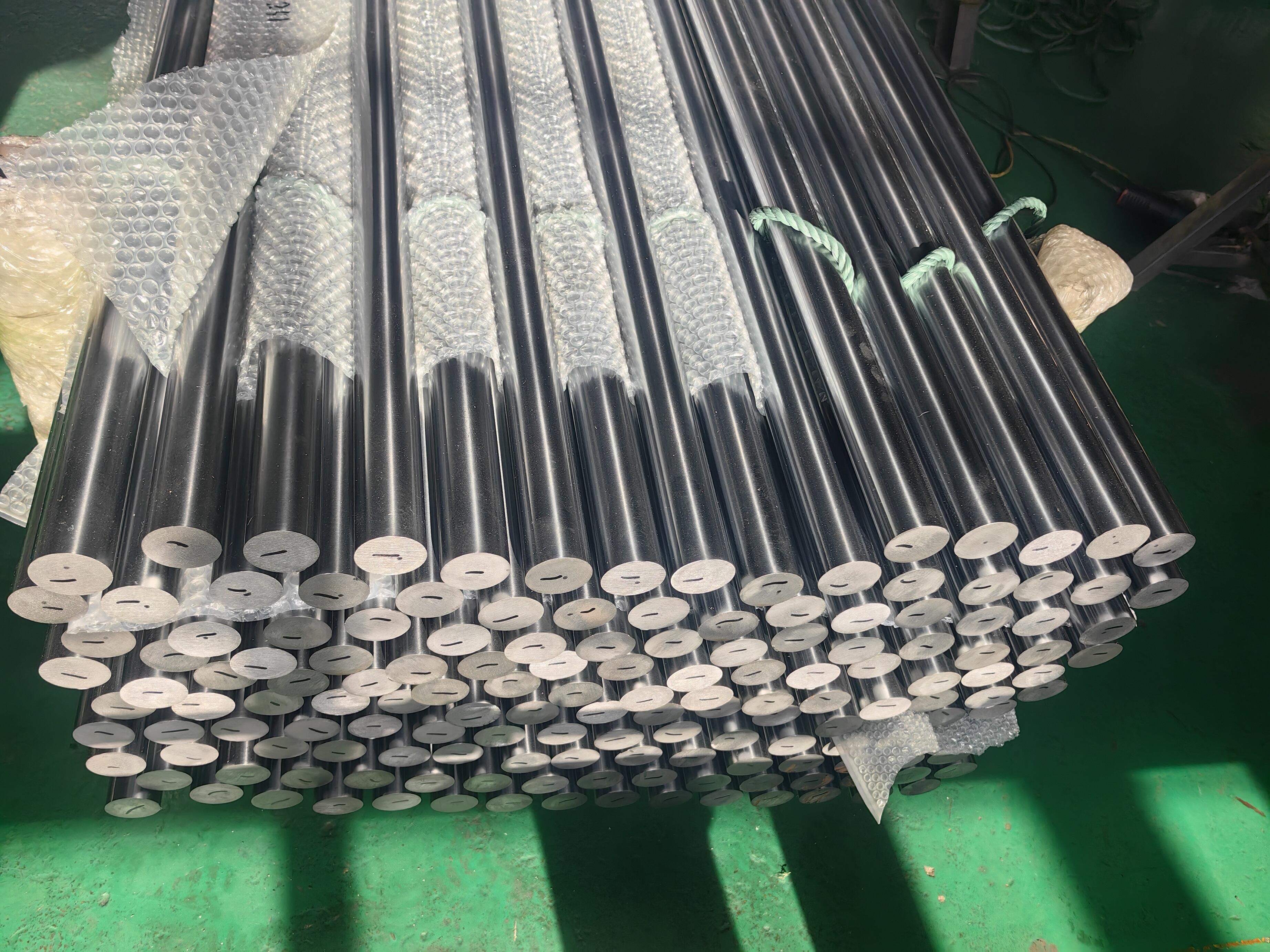

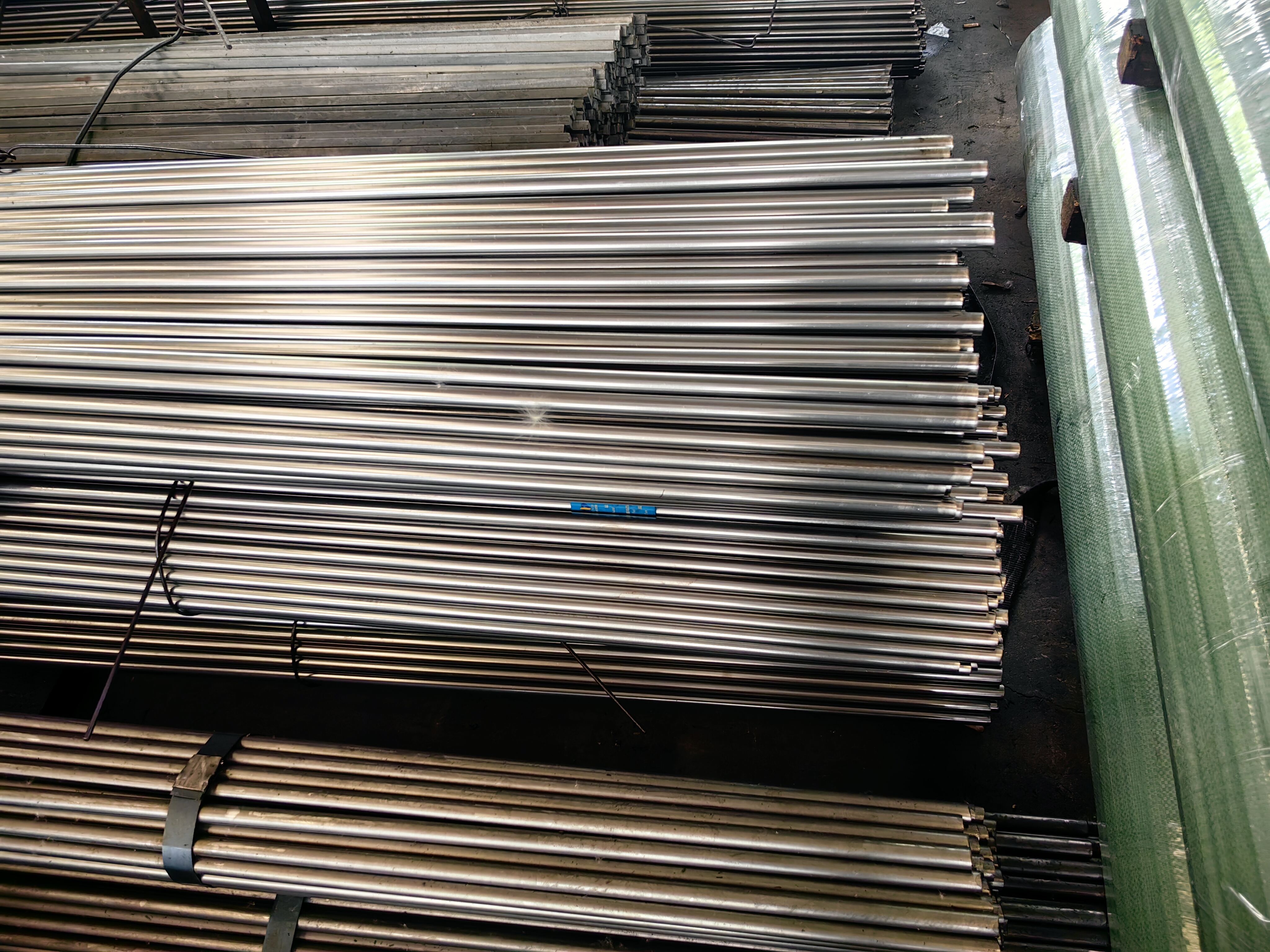

A high temperature alloys manufacturer represents a specialized industrial entity dedicated to producing advanced metallic materials capable of maintaining structural integrity and performance under extreme thermal conditions. These manufacturers focus on creating sophisticated alloy compositions that can withstand temperatures ranging from 1000°F to over 2000°F while preserving mechanical properties essential for critical applications. The primary function of such manufacturers involves developing, producing, and supplying heat-resistant materials through precise metallurgical processes including vacuum melting, powder metallurgy, and controlled atmosphere processing. The technological features of a high temperature alloys manufacturer encompass state-of-the-art furnace systems, advanced quality control laboratories, and specialized forming equipment designed to handle reactive materials. These facilities typically employ vacuum induction melting, electroslag remelting, and electron beam melting technologies to ensure chemical homogeneity and eliminate impurities that could compromise performance at elevated temperatures. The manufacturing processes incorporate strict temperature control, atmosphere management, and cooling rate optimization to achieve desired microstructures and mechanical properties. Applications for high temperature alloys span multiple industries including aerospace, power generation, petrochemical processing, and automotive sectors. In aerospace applications, these materials form critical components such as turbine blades, combustion chambers, and exhaust systems where weight reduction and thermal resistance are paramount. Power generation facilities utilize these alloys for steam turbine components, gas turbine hot sections, and nuclear reactor components where long-term reliability under thermal cycling is essential. The petrochemical industry depends on these materials for refining equipment, catalytic reforming units, and high-temperature piping systems that process corrosive substances at elevated temperatures. A high temperature alloys manufacturer must maintain rigorous certification standards including AS9100, ISO 9001, and NADCAP accreditation to meet aerospace and defense industry requirements while ensuring consistent quality and traceability throughout the production process.