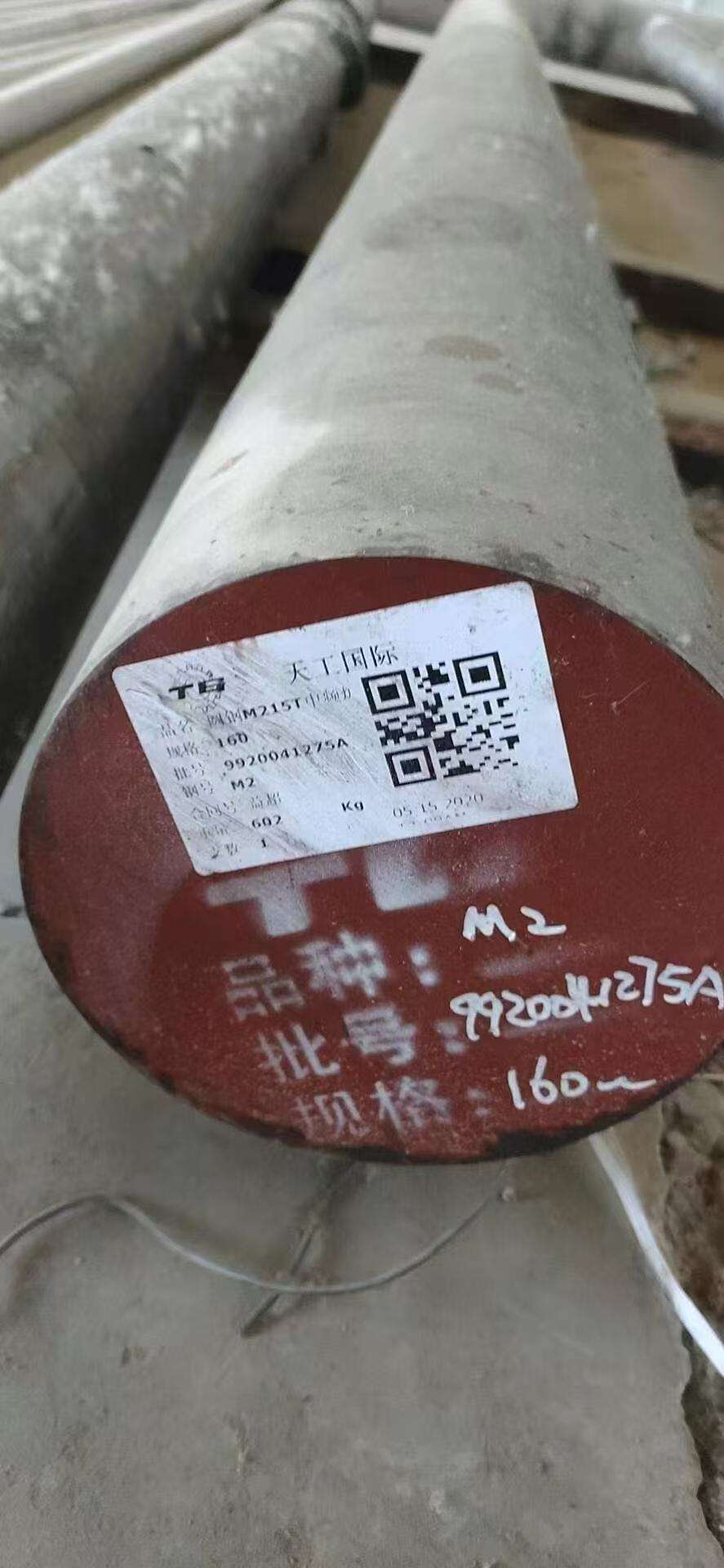

m2 tool steel

M2 tool steel represents one of the most versatile and widely utilized high-speed steel grades in modern manufacturing and machining applications. This molybdenum-tungsten based tool steel delivers exceptional performance characteristics that make it indispensable for demanding industrial operations. The composition of m2 tool steel typically includes approximately 6% tungsten, 5% molybdenum, 4% chromium, 2% vanadium, and 0.85% carbon, creating a balanced alloy that provides superior cutting performance and durability. The primary functions of m2 tool steel center around its ability to maintain hardness and cutting edge retention at elevated temperatures, making it ideal for high-speed machining operations where conventional steels would fail. This material exhibits remarkable red hardness, allowing tools manufactured from m2 tool steel to operate effectively at temperatures reaching 600°C without significant loss of performance. The technological features of m2 tool steel include excellent machinability in the annealed condition, superior grindability for precision tool manufacturing, and outstanding through-hardening capabilities that ensure uniform properties throughout the tool cross-section. Manufacturing processes benefit significantly from the consistent grain structure and predictable heat treatment response of m2 tool steel, enabling precise control over final tool properties. Applications for m2 tool steel span numerous industries, including aerospace, automotive, medical device manufacturing, and general machining operations. Common implementations include drill bits, end mills, reamers, taps, broaches, gear cutters, and various forming tools where reliability and performance cannot be compromised. The steel's ability to withstand shock loads while maintaining sharp cutting edges makes it particularly valuable for interrupted cutting operations and complex geometries where tool failure could result in costly production delays or quality issues.