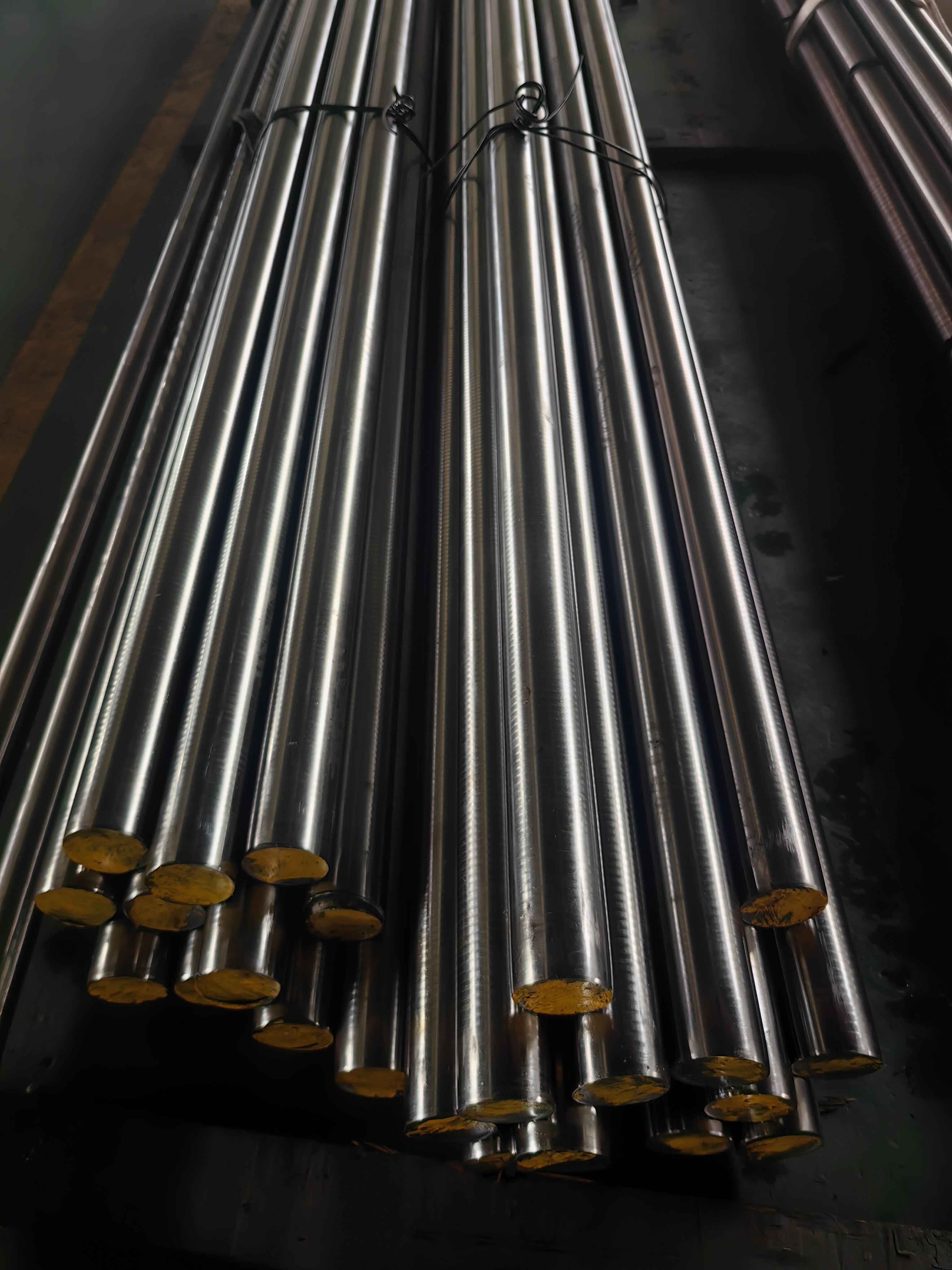

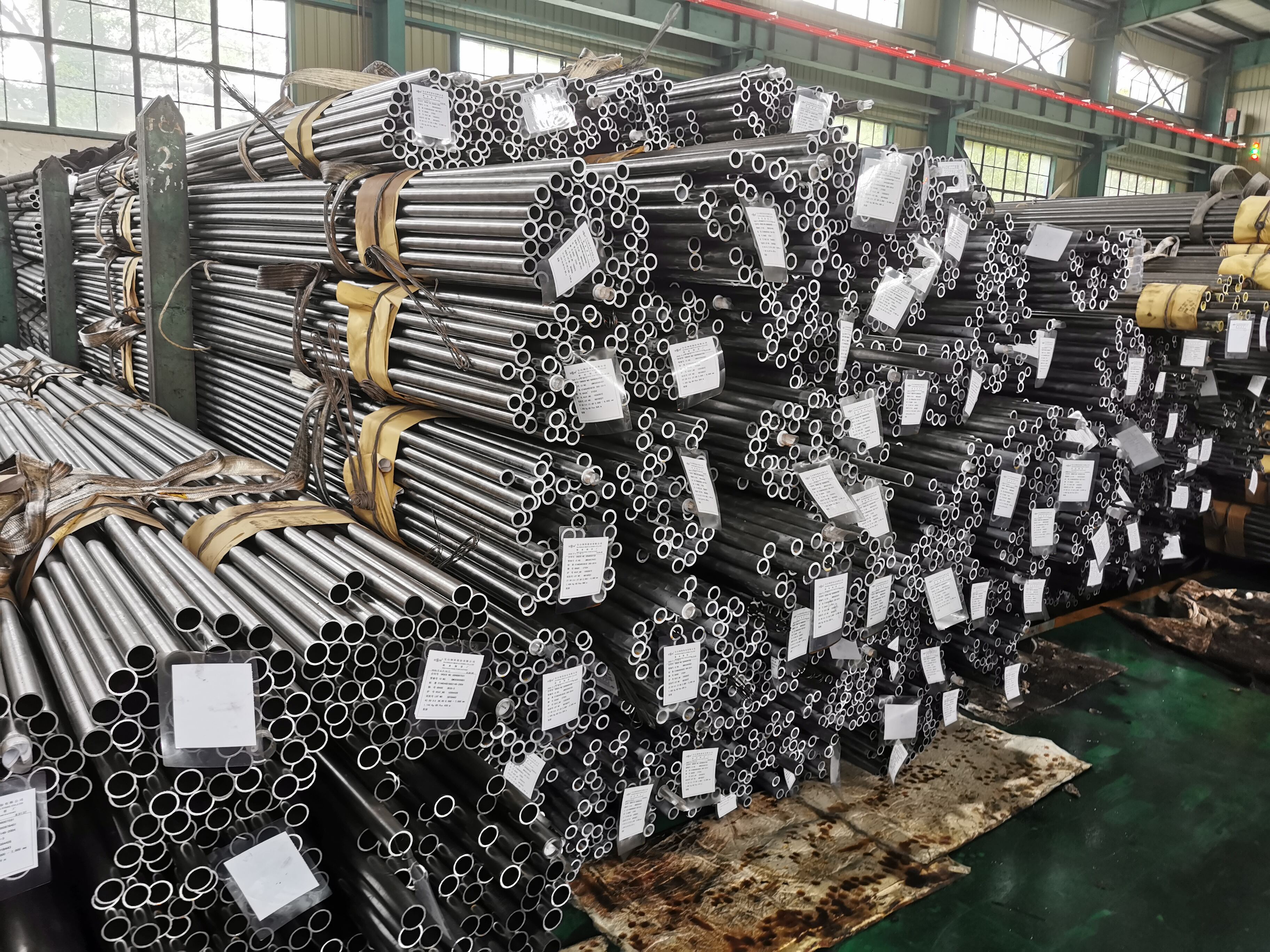

aisi 4340

El AISI 4340 representa uno de los aceros de baja aleación más versátiles y ampliamente utilizados en las aplicaciones industriales modernas. Este acero de cromo-níquel-molibdeno combina propiedades mecánicas excepcionales con una templabilidad sobresaliente, lo que lo convierte en un material indispensable en numerosos sectores. La denominación AISI 4340 sigue el sistema de clasificación del Instituto Estadounidense del Hierro y del Acero (American Iron and Steel Institute), donde los números indican elementos de aleación específicos y sus concentraciones aproximadas. El acero contiene aproximadamente un 0,40 % de carbono, un 1,65–2,00 % de níquel, un 0,70–0,90 % de cromo y un 0,20–0,30 % de molibdeno, lo que da lugar a una composición que ofrece características de rendimiento superiores. Las funciones principales del AISI 4340 consisten en proporcionar alta resistencia, excelente tenacidad y una notable resistencia a la fatiga en aplicaciones exigentes. Sus características tecnológicas incluyen una templabilidad profunda, que permite una penetración uniforme de la dureza en secciones gruesas, y una excelente respuesta a los procesos de tratamiento térmico. El acero presenta una mecanizabilidad superior en estado recocido y demuestra una soldabilidad excepcional cuando se siguen los procedimientos adecuados. El AISI 4340 encuentra aplicaciones extensas en componentes aeroespaciales, piezas automotrices, equipos para la industria del petróleo y el gas, material militar y maquinaria pesada. En el sector aeroespacial, este acero constituye la base de los componentes del tren de aterrizaje, piezas de motores de aeronaves y elementos estructurales que deben soportar condiciones extremas de esfuerzo. Los fabricantes automotrices confían en el AISI 4340 para ejes de transmisión, ejes, engranajes y bielas, donde la durabilidad y la fiabilidad son fundamentales. El sector del petróleo y el gas utiliza este material para manguitos de perforación, ejes de bombas y componentes de recipientes a presión que operan en entornos agresivos. Las aplicaciones militares incluyen cañones de armas de fuego, componentes blindados y piezas estructurales críticas que requieren relaciones máximas de resistencia respecto al peso. La versatilidad del acero se extiende también a la industria manufacturera, donde los componentes sometidos a altas tensiones exigen un rendimiento excepcional bajo condiciones de carga cíclica, lo que convierte al AISI 4340 en una opción ideal para aplicaciones críticas en diversos sectores industriales.