boiler tube fabrication

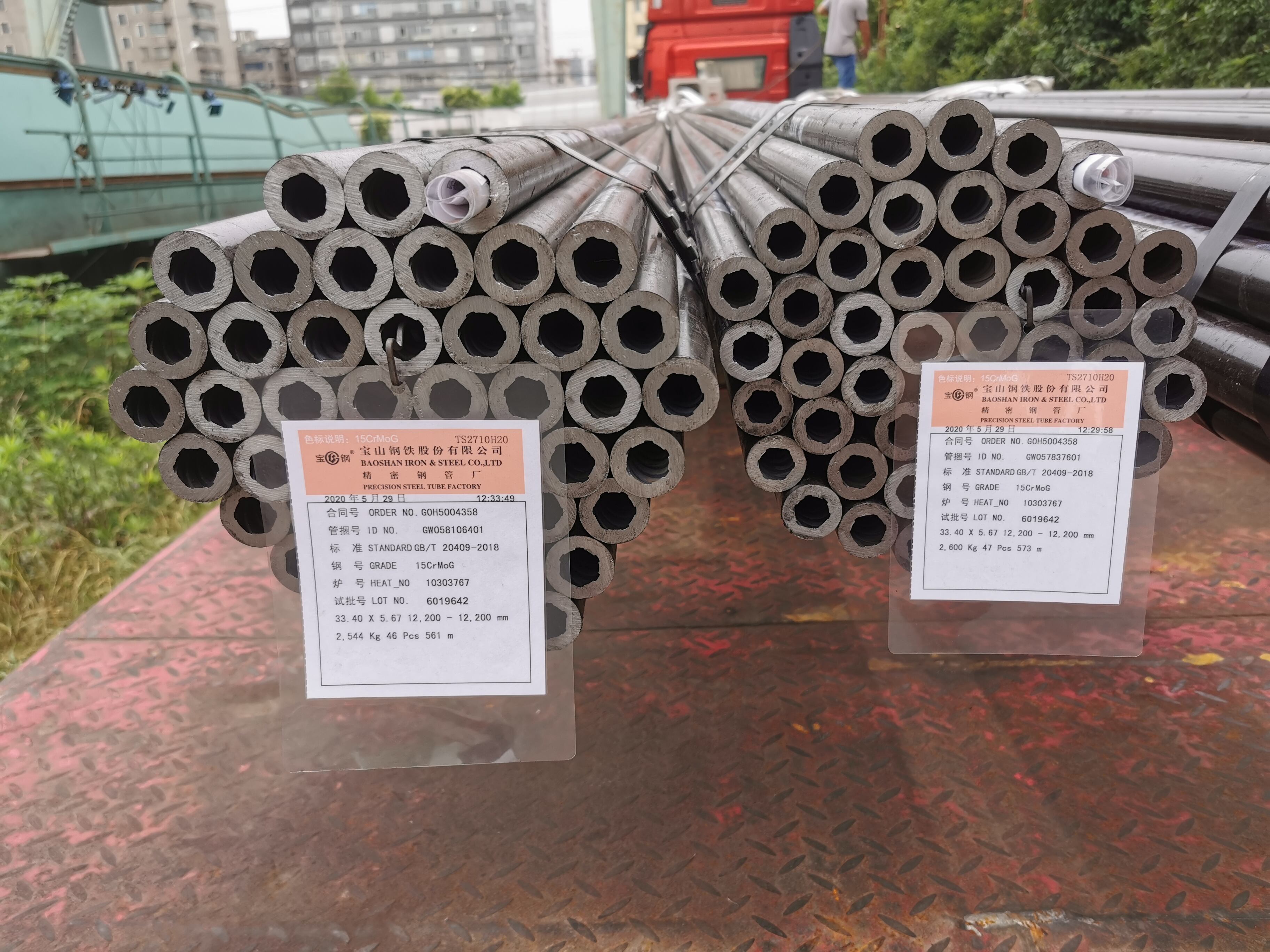

Boiler tube fabrication represents a critical manufacturing process that creates essential components for steam generation systems across multiple industries. This specialized fabrication involves the precise engineering and construction of tubes designed to withstand extreme temperatures, high pressure conditions, and corrosive environments found within boiler systems. The primary function of boiler tube fabrication centers on producing heat exchanger elements that efficiently transfer thermal energy from combustion gases to water, converting it into steam for power generation, heating, or industrial processes. Modern boiler tube fabrication employs advanced metallurgical techniques, incorporating materials such as carbon steel, alloy steel, stainless steel, and specialized super alloys depending on specific operational requirements. The technological features of contemporary boiler tube fabrication include computer-controlled bending machines, precision welding systems, and automated quality control measures that ensure dimensional accuracy and structural integrity. These tubes must meet stringent industry standards including ASME, ASTM, and international specifications to guarantee safe operation under demanding conditions. The fabrication process encompasses multiple stages including material selection, cutting, forming, welding, heat treatment, and comprehensive testing protocols. Applications for boiler tube fabrication span diverse sectors including power plants, petrochemical facilities, refineries, paper mills, food processing plants, and commercial heating systems. Each application demands specific tube configurations, wall thickness requirements, and material compositions tailored to operational parameters such as operating temperature, pressure ratings, and chemical compatibility. Quality assurance throughout the boiler tube fabrication process involves non-destructive testing methods including ultrasonic inspection, radiographic examination, and hydrostatic pressure testing to verify structural soundness and performance capabilities before installation.